Has your old Aston Martin got a Webasto sunroof fitted? Want to replace it? Contact us for more details.

1976 AUSTIN MINI CLUBMAN ESTATE RESTORATION

The restoration of a 1976 Mini Clubman Estate is a journey into automotive history, breathing new life into a classic British icon. Known for its distinctive design, compact size, and versatile estate body, the Mini Clubman Estate has become a beloved symbol of 1970s motoring. This restoration project involves meticulous attention to detail, from repairing the aging bodywork and reviving the engine to updating the interior for modern comfort while maintaining its vintage charm. The goal is to preserve the Mini’s unique character, ensuring that this piece of automotive history continues to turn heads for generations to come.

Step 1

Collection of vehicle!

Step 2

Strip down and assessment

Step 3

Prepare shell for media blasting.

Media blasting is a process used in classic car restoration to strip old paint, rust, and contaminants from the car’s surface. By blasting abrasive materials like sand or glass beads with pressurized air, it reveals the true condition of the metal, making repairs easier and more accurate. This technique is especially useful for hard-to-reach areas, and when done properly, it preserves the integrity of the body while ensuring a clean, smooth surface for painting. However, it requires expertise to avoid damaging delicate panels.

Facel Vega Restoration

1962 Facel Vega II Coupé

The ex-Earls Court Motor Show

1962 Facel Vega II Coupé

Registration no. 3 GXK

Chassis no. HK2 B 148

Engine no. TY8-613270

The Restoration Journey gallery…

Ferrari 400 Restoration

1981 Ferrari 400i Restoration Diary

The Ferrari 400i, a model that embodies the pinnacle of 1980s luxury and performance, is a true testament to Ferrari’s commitment to blending elegance with power. The 1981 Ferrari 400i, a beautifully crafted GT car, might not have the instant name recognition of the iconic Ferrari 308 or 512, but it remains a cherished piece of automotive history. For enthusiasts and collectors, restoring a 1981 Ferrari 400i isn’t just about bringing back a car to its former glory—it's about preserving a piece of Italian craftsmanship, rich history, and unforgettable driving experience.

The Ferrari 400i: A Brief Overview

Before diving into the intricacies of restoration, it's important to understand what makes the 1981 Ferrari 400i such a unique and desirable vehicle. Produced between 1979 and 1985, the 400i is part of the Ferrari 400 series, known for its luxurious Grand Tourer (GT) design. Unlike Ferrari’s more track-oriented models, the 400i was built for comfort without sacrificing performance. It was powered by a 4.8-liter V12 engine, a front-mounted masterpiece that delivered a silky smooth driving experience and enough power to make any road feel like a private track.

While the Ferrari 400i might not boast the same raw, racing-inspired energy of some of Ferrari’s other models, it’s revered for its ability to combine high performance with sophistication. It was Ferrari’s way of catering to a different type of driver: one who valued long, fast drives through winding roads just as much as outright speed.

We’ll be carrying out the following:

Full engine rebuild (4.8 litre V12 engine fuel-injected and has a Bosch K-Jetronic system)

Full interior re-trim using correct Connolly leather.

Bodywork and paintwork carried out to exacting standards.

Electrical, mechanical and suspension upgrades and repairs.

Follow us along the way or ‘learn more’ below.

The Restoration Process: A Fine Balance of Art and Engineering

Restoring a 1981 Ferrari 400i isn’t something that can be taken lightly. Like all classic Ferraris, the restoration requires precision, patience, and a keen understanding of both the car’s mechanical and aesthetic values. Below, we’ll break down the various steps and key areas that demand attention during the restoration of a Ferrari 400i.

1. Engine Rebuild…

The heart of any Ferrari is its engine, and the V12 in the 400i is no exception. Over time, engines inevitably suffer wear and tear, and the 4.8-liter unit in the 400i is no different. Restoring this engine involves complete disassembly, inspection, and cleaning of all components. Major parts such as pistons, camshafts, and valve seats are often replaced to ensure that the engine operates at its original performance level.

The fuel injection system, a significant upgrade over the earlier carbureted Ferrari 400, also requires attention. The 400i used Bosch K-Jetronic mechanical fuel injection, which, though reliable, may have issues with age. Restoring this system to full functionality can improve overall fuel efficiency and throttle response.

A typical Ferrari 400i engine rebuild also involves checking the cooling system, timing belt, and all electrical components to ensure that the car runs as smoothly as it did when it first left the factory. It's worth noting that Ferrari’s original specifications for engine tuning are a benchmark to aim for during restoration—though some owners might opt to make modifications for improved reliability or power.

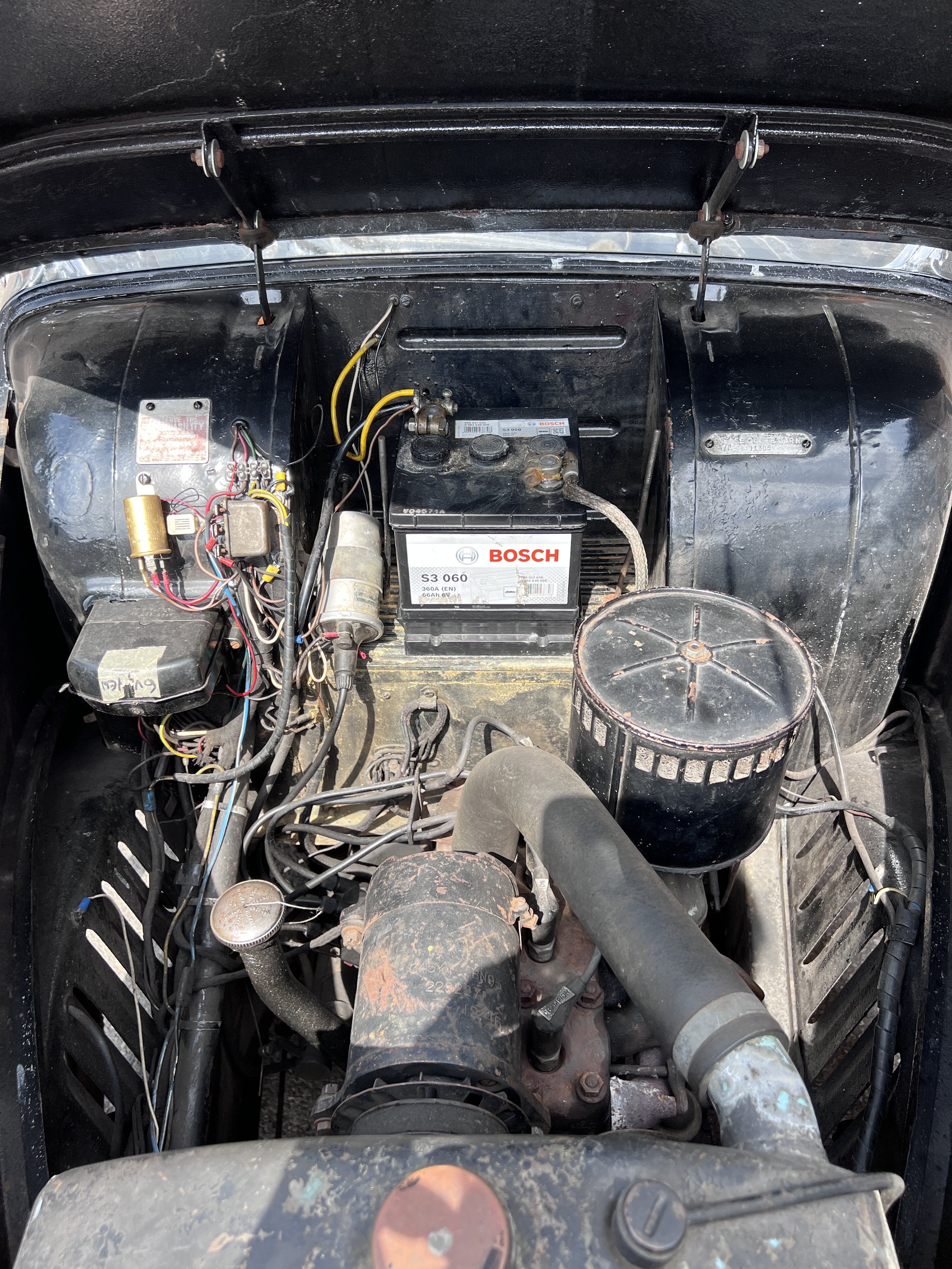

Further Engine Images:

2. Bodywork and Paint…

Like any restoration, the bodywork plays a pivotal role in bringing the Ferrari 400i back to life. The 400i’s design is timeless, with smooth, flowing lines and an understated elegance. However, as with all classic cars, rust and age can take their toll on the exterior. Body panels often require a thorough inspection to check for corrosion, especially around the wheel wells, rocker panels, and underbody.

Any signs of rust are addressed early on with a process called “media blasting,” where the old paint and rust are carefully removed without damaging the underlying metal. Once the body is restored to its original condition, the paintwork is done with a high-quality, period-correct Ferrari colour to bring it back to its original shine.

Bodywork upon arrival:

3. Suspension, Brakes, and Drivetrain…

The suspension and drivetrain systems in the Ferrari 400i need careful attention to ensure the car handles like a Ferrari should. Over time, suspension components such as bushings, dampers, and springs can wear out, resulting in a less responsive, more uncomfortable driving experience. These parts must be inspected, refurbished, or replaced as needed.

The 400i’s braking system, while advanced for its time, also needs to be brought back to full functionality. This includes inspecting the brake lines, callipers, and discs, and replacing any parts that show excessive wear. After all, a Ferrari is meant to be driven, and ensuring the braking system performs at its peak is critical.

4. Interior Restoration: Luxury and Comfort…

The interior of the 1981 Ferrari 400i is where much of the luxury experience shines through. The leather upholstery, wood veneers, and refined dashboard layout make it feel like a luxurious place to spend long hours on the road. However, age can be especially tough on these materials.

The leather seats often show signs of cracking, fading, and wear. Reupholstering with high-quality leather—usually in a colour that matches the car’s original interior scheme—is a must. The dashboard and centre console components, often made from wood or faux wood, can deteriorate over time, so refinishing or replacing them is part of the restoration process.

Special attention is given to the steering wheel, as well, as it often shows signs of wear. Depending on the condition, the original wheel can be restored, or a period-correct replacement can be sourced to ensure the interior looks and feels just like the car did when it first left the showroom.

See images below of the car upon arrival with us.

The Ferrari 400i: February update…

Maserati 3500 Carburettor Rebuild

Weber 42 DCOE Carburettor rebuild

January 2025:

Poor running on this Maserati 3500 GT called for inspections into Carburettors.

As we were unable to balance them, the decision was made to remove them.

All 3 Weber 42 DCOE Carbs and spindles were stripped down and we found sticky bearings due to grit, the butterflies lactated into position and not centralised. We carried out a full overhaul and replace, bearings, springs, seals and gaskets, centralise butterflies and check for closure on both butterflies. Loctite spindle screws.

The carburettors are now complete. Everything was available except the spindles. I replaced the sticky bearings and then fitted spindle shaft kits to do this everything had to be removed. I also found the chokes sticking so they now close off.

One carburettor has 0.03” and 0.02” gap previously 0.012”

The other carburettor has 0.01” and 0.03” previously 0.014”

So I’m very happy how they have turned out.

1973 Ferrari 246 GTS Dino Restoration

Arrival

Closer details

Alfa Romeo 105 Series Restoration

Aston Martin DB4 Restoration

Aston Martin DB5 Restoration

Ferrari 250 GT Lusso Restoration

Aston Martin DBS V8 Restoration

1971 Aston Martin DBS V8 Restoration

Alfa Romeo 1900 Restoration

Mercedes 190 SL Restoration

Audi RS4 Refurbishment

1939 Austin 8 Tourer

The Prestige Team have been tasked with carrying out a ‘Sympathetic Restoration’ to this lovely 1939 Austin 8 Tourer.

Having not only survived WWII, it’s also been in the same family for over 80 years, therefore retaining some of its lovely patina and originality is of the utmost importance.

Aston Martin V8 Vantage Restoration

1979 Aston Martin V8 Vantage

Metal and paintwork restoration carried out in 2018.

1973 Aston Martin AM Vantage Restoration

Looking back on an old restoration, carried out with us in 2015 the car is currently back for servicing and maintenance before it heads off to Europe for the Summer.

We thought this would be a good opportunity to look back on this project and share some photographs with you. Here are some taken of the car, sat outside Botleys Mansion on a beautiful Summers day in 2016.

(Photo credit to reef-design.co.uk)

The AM Vantage, released in May 1972 alongside the visually similar V8 and with an engine virtually identical to that of the DB5.

Production of the car lasted for just over a year with only 70 examples having been built, 68 with right hand drive.

This particular car has triple weber carburettors and was also Victor Gauntlett’ personal car built for him in 1973, hence why this is such a highly specified and special vehicle.

Carry on reading for a brief summary of this restoration.

Tadek Marek designed 4.0-ltr, 6-cylinder engine.

Visual differences between the AM V8 and DBS can be seen below. With credit to astonmartins.com. (Astonmartins.com)

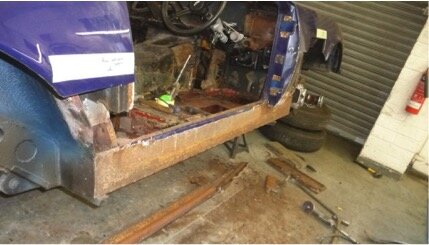

Once the vehicle was stripped down, we began by removing the front end from the body, there we discovered a previous poor job on the wing. This was corrected and re-welded.

We also fitted new inner wing panels and new outriggers on the O/S and N/S.

Inner and outer sills were fabricated using mild steel and fitted due to corrosion.

Further areas were attended to including the engine bay and wheel arches.

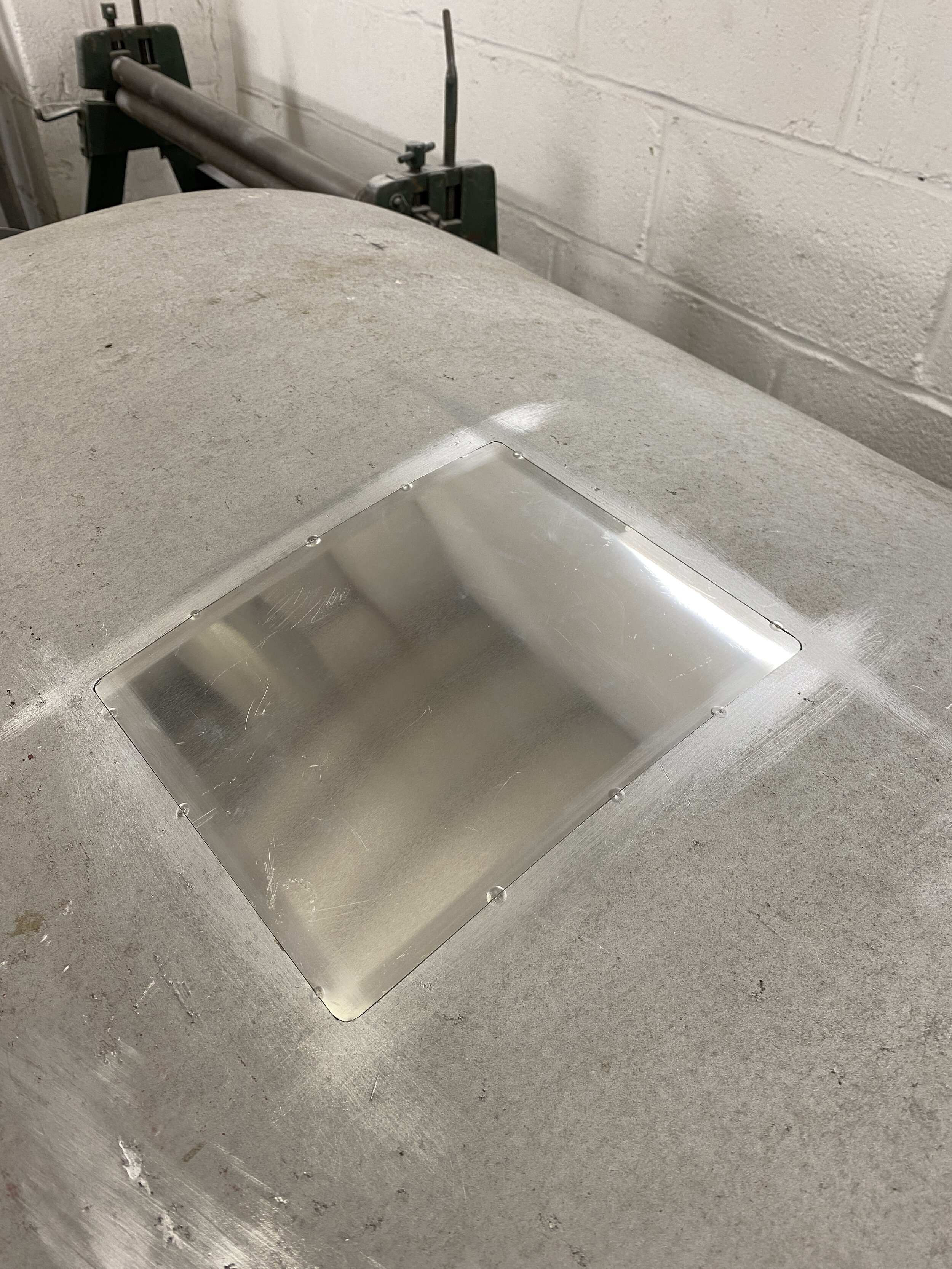

We fabricated two new door skins in aluminum, once the door frames were media blasted we made some necessary repairs and fitted the skin to the frame. The doors subsequently had gapping along with the bonnet and boot lid.

The six-cylinder 4 litre engine and gearbox was cleaned and detailed.

Along with this, the cylinder head, fan motor, starter motor and alternator were overhauled. Plus the radiator and heater matrix.

A complete wiring loom was replaced in the car.

Whilst the vehicle was stripped to bare metal and painted the exterior chrome parts were sent to our trusted partner for high quality re-chroming.

The car was fitted with new headlights, front grille, wire wheels and tyres.

The interior was completely re-trimmed in Connolly magnolia leather with navy blue piping by our coach trimmer Mike.

Seat belts were replaced including new clasps, steering wheel, dash and console also re-trimmed.

Final checks with James before she went home to be enjoyed by her owner.

Thinking of carrying out a similar Aston Martin project, be sure you have found the best company with a commitment to excellence and all of the core values of a family run business.

Some previous Aston Martin projects include Peter Agg’ DB3S, DB2/4, DB4, DB4 GT, DB5, DB6, DB6 Shooting brake, V8 and DBS. We will get round to blogging about these soon but photographs can be seen in our gallery. Click Here

Please get in touch to discuss your requirements over the phone or by using the form below.

1932 Alvis Speed 20 Restoration

The Alvis Speed 20 is a British touring car that was made between late 1931 and 1936 by Alvis Car and Engineering Company in Coventry.

The owner of this lovely car got in touch with us at the end of 2020, hoping that we would be able to help him with some metalwork requirements, and he came to the right place.

Harry and Grant from our coachbuilding team got straight to work fabricating panels using the English Wheel and making repairs where needed.

See below for a small selection of photographs of this fantastic project.

Mercedes 280SL Pagoda

This week brings a 1969 Mercedes 280SL Convertible into the mechanical shop.

Having spent over 2 years in storage we set about getting the car running.

A nasty fuel leak was spotted and the tank was removed and flushed of old fuel before replacement of perished fuel lines.

2.8-litre six-cylinder engine produced 180bhp, 20 horsepower more than the preceding 250SL's

After a full assessment on the ramp we had to deal with some oil and fluid leaks. The engine sump gasket and gearbox sump gasket were replaced and our mechanical technicians carried out a full service.

After road testing and detailing the car was delivered back to its owner ready to be enjoyed this Summer.

Whether it is an annual service, mechanical or bodywork we are here to help you enjoy your car again so please do get in touch to discuss your requirements.